FDA-Certified Silicone Tubing - Platinum/Peroxide-Cured for Medical & Laboratory Use

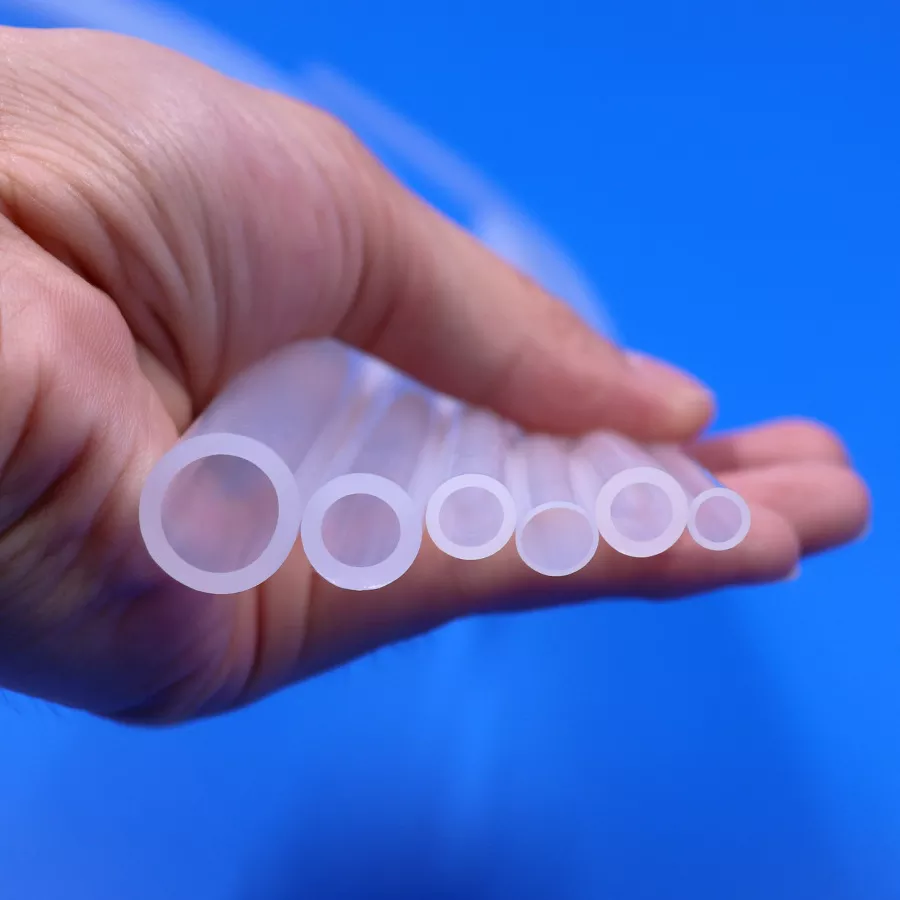

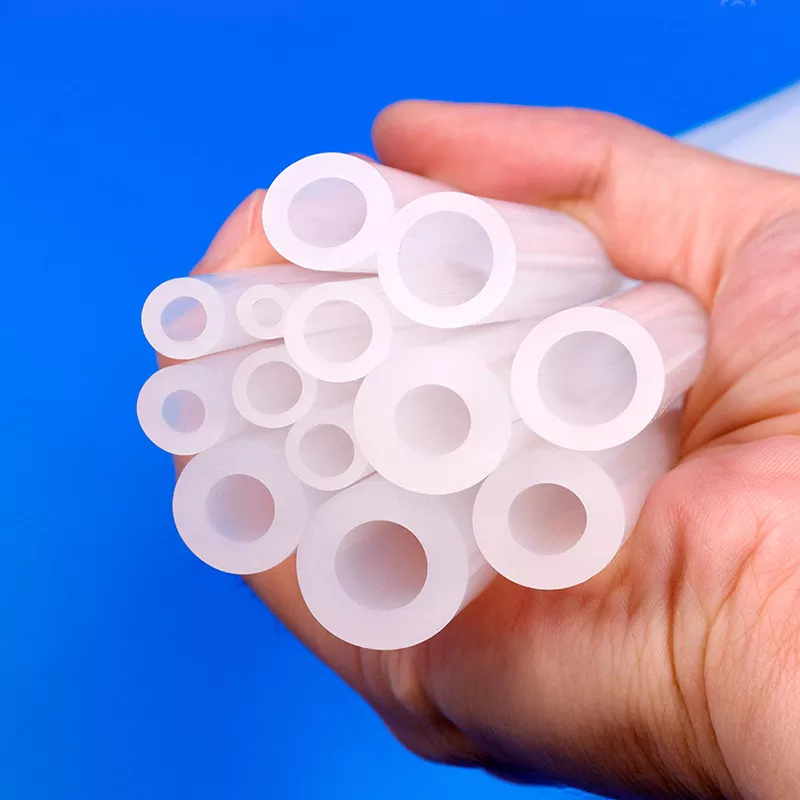

The tubes are available in natural, transparent, translucent, or custom colors according to the Pantone color card, with a cross-section size range of 3–30 mm. They offer outstanding temperature resistance from –60°C to +250°C, maintaining stable performance in extreme environments. With a hardness range of 30–80 Shore A, tensile strength of 6–12 MPa, elongation of 200–700%, and tear strength of 10–25 kN/m, the material provides excellent mechanical stability, elasticity, and wear resistance. The density ranges between 1.1–1.3 g/cm³, ensuring a balance of light weight and strength.

Packaging options include custom-cut lengths or standard coils (25 m, 50 m, or 100 m), with a minimum order quantity (MOQ) of 1000 meters.

Technical Specifications

| Specification Item | Details |

| Product Name | FDA-Certified Silicone Tubing for Medical & Laboratory Use |

| Product Type | Platinum-cured / Peroxide-cured |

| Product Features | RoHS / REACH compliant / FDA 21 CFR 177.2600 |

| Product Application | Medical and pharmaceutical tubing, Laboratory equipment |

| Color | Natural, Transparent, Translucent, Custom (Pantone-matched) |

| Temperature Range | –60°C to +250°C |

| Cross Section Size | 3–30mm |

| Tear Strength | 10–25 kN/m |

| Hardness | 30–80 Shore A (common: 40, 50, 60) |

| Density | 1.1–1.3 g/cm³ |

| Elongation | 200–700% |

| Tensile Strength | 6–12 MPa |

| Package | Custom cut or standard coil (e.g., 25 m, 50 m, 100 m) |

| MOQ | 1000M |

Product Advantage

Complete range of specifications

Customizable colors, sizes, and shapes, safe, odorless, and environmentally friendly.

High and low temperature resistance

Temperature resistance -20°C-200°C, pressure resistance, and aging resistance.

Food-grade silicone hose

Customization available, sample turnaround within three days, quality guaranteed.

Excellent flexibility

Excellent resilience, with tensile strength and no deformation.

Premium materials

Smooth surface, free of impurities and burrs

Cutting and processing

Size and length can be customized as needed.

Why Choose Our Silicone Square Strip?

Our silicone gaskets deliver exceptional temperature, UV, and ozone resistance, ensuring reliable performance in both extreme heat and cold. They maintain flexibility and sealing integrity from -60°C to +230°C, outperforming many alternative materials.

We specialize in custom profiles and formulations—offering tailored durometers, colors, and shapes to match exact application needs. Our tight tolerance control and consistent cross-section quality ensure perfect fit and long-term reliability.

Our silicone compounds meet industry standards (FDA, UL, ASTM, and NSF as required) and provide long service life even in harsh environments. This means fewer replacements, reduced downtime, and lower total cost of ownership.

We don’t just sell gaskets—we partner with customers from design to production. Our in-house engineering support, quick prototyping, and reliable lead times help customers move from concept to finished product faster.

Product Application

Our Silicone Square Strip is engineered for sealing, dustproofing, waterproofing, and anti-collision in high-demand industrial scenarios, delivering reliable performance across electronics, automotive, and construction sectors. Below are key application scenarios and use cases:

1. Electronics Industry

Sealing for electronic enclosures, PCB boards, and power supply units (PSUs) to prevent dust, moisture, and debris intrusion

Gap filling and vibration damping for consumer electronics (e.g., smartphones, laptops) and industrial control panels

Thermal insulation for high-temperature electronic components, maintaining stability in -40°C~+280°C operating environments

2. Automotive Industry

Door/window sealing, trunk weatherstripping, and engine compartment gaskets (resisting engine heat and road debris)

Sealing for automotive lighting fixtures, battery packs, and EV charging ports (waterproof and aging-resistant)

Anti-collision and noise reduction for interior trim gaps (soft texture, pressure-resistant, and durable)

3. Construction Industry

Window/door frame sealing, curtain wall gap filling, and glass installation gaskets (waterproof, dustproof, and weatherproof)

Sealing for HVAC systems, plumbing pipelines, and building expansion joints (adapting to temperature fluctuations)

Decorative and protective edging for architectural panels (smooth surface, consistent cross-section, and long-term durability)

4. Other Industrial Fields

Sealing for medical equipment (compliant with hygiene standards, non-toxic and odorless)

Gaskets for kitchen appliances (e.g., ovens, dishwashers) with high-temperature resistance up to +280°C

Customized sealing solutions for machinery, aerospace components, and marine equipment (tailored sizes and hardness)

Ideal for scenarios requiring tight sealing, extreme temperature resistance, and long service life—our silicone square strip ensures operational reliability and reduces maintenance costs for industrial applications.

Shenzhen ESMAI Technology Co., Ltd.

Headquartered in Shenzhen, China, we provide one-stop solutions for custom silicone extruded gaskets and seals, from material formulation to precision post-processing, serving as a reliable OEM/ODM partner worldwide. Backed by strong engineering expertise, our 3,000+㎡ production base with 10+ high-precision extrusion lines supports both prototyping and mass production (daily output up to 30,000 meters), while adhering to ISO 9001:2015, RoHS, REACH, UL 94 V-0, and FDA standards for strict quality and traceability. We deliver efficient services, including custom molds in 3–5 days, samples in 3–7 working days, and mass production in 10–20 working days, all supported by global logistics.

Our highly customizable products stand out for superior durability (resistant to UV, chemicals, and extreme temperatures up to 315°C), easy installation, and tight dimensional precision, making them ideal for automotive, LED lighting, electronics, HVAC, medical, construction, and solar industries. We’ve provided stable solutions for global customers, and adhering to quality-first and customer-centric principles, we sincerely invite long-term cooperation and welcome your inquiries.

Product performance is stable, patents are complete, safety and quality are guaranteed.

Got Questions? Well, We've Got Answers.

We have experience in extrusion, in-house tooling, quality certifications (ISO, FDA, USP, NSF), and the ability to customize profiles to your exact needs. we also provide samples and technical support.

For standard profiles: often stocked and ready to ship , for custom extrusions: typically 2–4 weeks for tooling and production time. we can also offer expedited services if customer is in great hurry for the product.

We will go beyond extrusion by providing

1),Splicing into O Rings gaskets

2)Cut-to-length services

3)Adhesive backing/tape application

4)Wind into rolls

Yes, a strong supplier should offer stock profiles (D, P, E, U, bulb seals, cords, etc.) and custom designs for unique requirements. Customization is key if your project has specific sealing needs.

Yes, we have in-house die-making capabilities, allowing faster customization and better quality control.

We usually provide prototype samples or small trial runs so you can test fit, compression, and performance before committing to full orders.